Place of Origin : Hebei,China

Hydroxypropyl Methylcellulose (HPMC) is a key ingredient used in various industries, including construction and building materials. HPMC is a cellulose ethers derived from plant fibers. It is odorless, tasteless, non-toxic, and has excellent water solubility, making it a versatile additive in a wide range of applications.

Hydroxypropyl Methylcellulose (HPMC) Is A Key Ingredient Used In Various Industries, Including Construction And Building Materials. HPMC Is A cellulose Ethers Derived From Plant Fibers. It Is Odorless, Tasteless, Non-toxic, And Has Excellent Water Solubility, Making It A Versatile Additive In A Wide Range Of Applications.

Importance Of HPMC In Dry Mix Mortar:

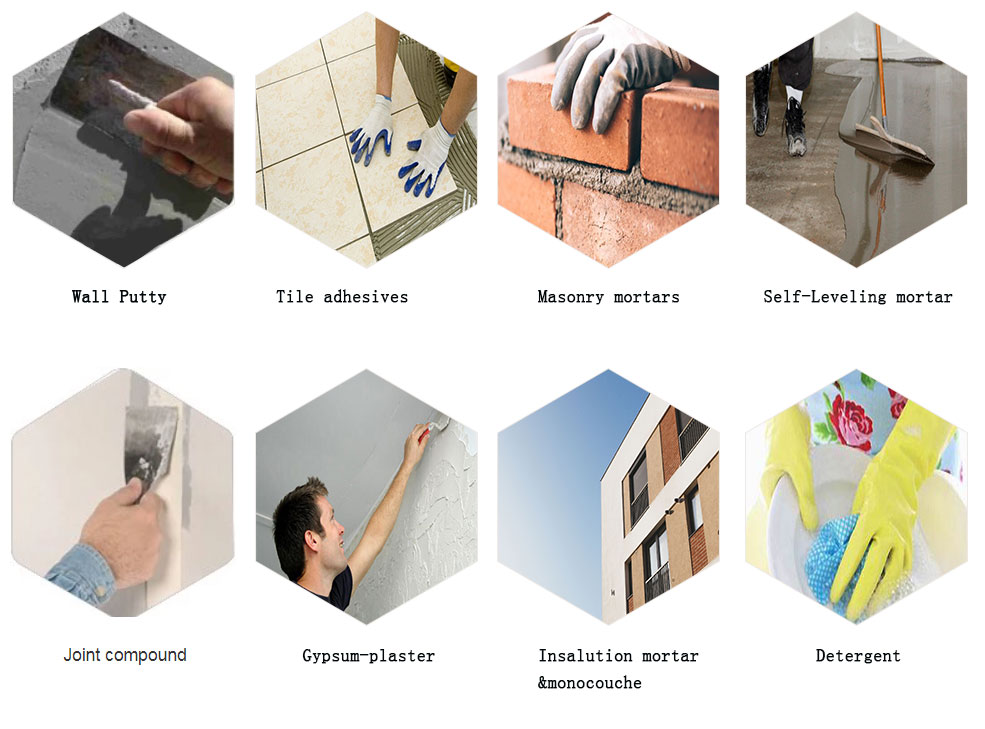

Dry Mix Mortar, Also Known As Dry Mortar, Is A Mixture Of Cement, Sand, And Additives Used For Various Construction Applications, Such As Tile Adhesives, Plastering, Masonry Mortars, And Grouts. HPMC Is Commonly Used As An Additive In Dry Mix Mortar Due To Its Beneficial Properties. Here Are Some Reasons Why HPMC Is Widely Used:

Water Retention: HPMC Improves The Water Retention Capacity Of Dry Mix Mortar, Preventing Rapid Evaporation Of Water During The Setting And Curing Process. This Property Ensures Sufficient Hydration Of Cement And Helps In Achieving Better Strength Development.

Workability: HPMC Acts As A Rheology Modifier, Enhancing The Workability And Spreadability Of Dry Mix Mortar. It Improves The Consistency And Reduces Sagging, Allowing For Easier Application And Better Coverage.

Improved Adhesion: HPMC Enhances The Adhesion Properties Of Dry Mix Mortar, Promoting Better Bonding Between The Mortar And Various Substrates. This Is Particularly Important In Tile Adhesives And Plastering Applications, Ensuring Durable And Long-lasting Results.

Crack Resistance: HPMC Imparts Increased Flexibility To Dry Mix Mortar, Minimizing The Risk Of Cracking Due To Shrinkage Or External Stresses. It Improves The Overall Durability And Performance Of The Mortar, Reducing Maintenance Requirements.

Sag Resistance: HPMC Helps Prevent Sagging And Slumping Of Dry Mix Mortar During Vertical Applications. This Ensures Uniform Thickness And A Smooth Finish On Walls, Ceilings, And Other Vertical Surfaces.

Introducing Our Company:

We Are A Leading Provider Of High-quality HPMC For The Construction Industry. With Years Of Expertise And A Commitment To Innovation, We Strive To Deliver Reliable And Effective Solutions To Our Customers.

we Understand The Importance Of Using Superior Additives Like HPMC To Enhance The Performance Of Dry Mix Mortar. Our HPMC Products Are Manufactured Using State-of-the-art Processes And Undergo Stringent Quality Control Measures To Ensure Consistent And Reliable Performance.

We Take Pride In Our Customer-centric Approach, Offering Technical Support, Customized Solutions, And Prompt Delivery Services To Meet The Diverse Needs Of Our Clients. Our Team Of Experts Is Dedicated To Providing Exceptional Customer Service And Assisting You In Achieving The Best Results With Our HPMC Products.

Choose Us For All Your HPMC Requirements And Experience The Difference In The Performance And Quality Of Your Dry Mix Mortar Projects.

Tags