Place of Origin : Henan,China

Delivery Time : 14 Days

Description

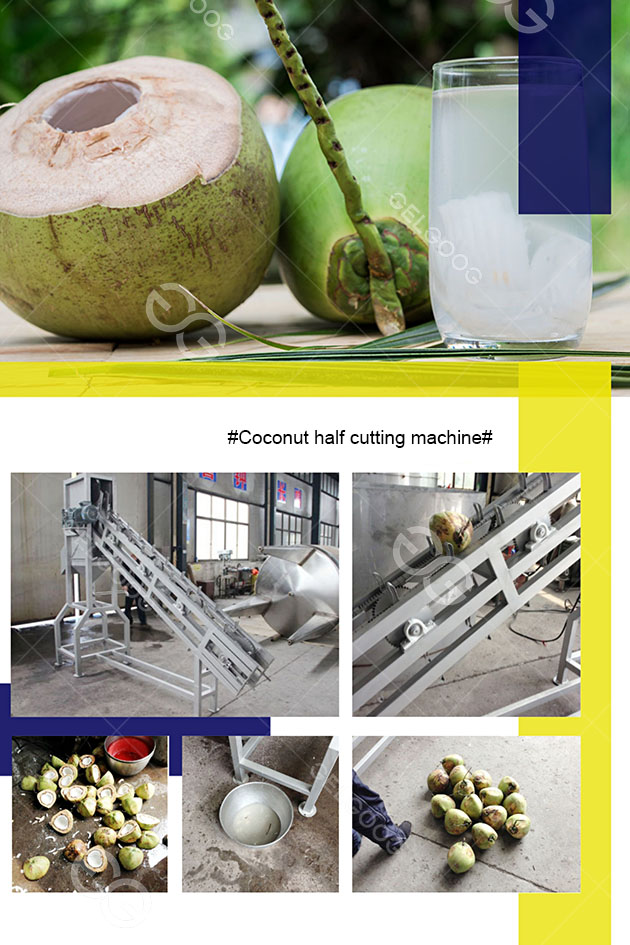

For the harvesting of coconuts after they are mature, it is commonly used in the market to remove the thick fiber from the outside by manual or mechanical rollers, and then use a sharp awl to chisel the brown core. Hole, put the straw into the coconut milk, so that the operation method of the coconut is not only inefficient and labor-intensive, but at the same time, the value utilization rate of the coconut is also greatly reduced.

For The Harvesting Of Coconuts After They Are Mature, It Is Commonly Used In The Market To Remove The Thick Fiber From The Outside By Manual Or Mechanical Rollers, And Then Use A Sharp Awl To Chisel The Brown Core. Hole, Put The Straw Into The Coconut Milk, So That The Operation Method Of The Coconut Is Not Only Inefficient And Labor-intensive, But At The Same Time, The Value Utilization Rate Of The Coconut Is Also Greatly Reduced. The Coconut Cut Half Juicer Machine Developed And Manufactured By Our Company Is Used As The Pre-equipment In The Coconut Production Line To Provide A Mechanized Operation With High Extraction Rate And Stable Operation For The Extraction Of Coconut Milk And Coconut Meat. At The Same Time, The Coconut Shell Cut In Half Can Also Be Run To The Next Process For Coconut Meat Extraction.

This Coconut Half Cutting Machine Is Suitable For Halving Coconuts. The Machine Is Designed With Compact Structure, Low Noise And Convenient Use. The Whole Is Made Of Stainless Steel.

The Coconut Half Cutting Machine Is Mainly Composed Of Important Parts Such As Frame, Conveying Chain, Juice Hopper, Slag Hopper, Shift Frame, Transmission Reducer And So On.

Its Main Working Principle: After Manually Placing The Coconut On The Baffle Of The Conveyor Chain, It Is Driven By The Driving Shaft To Move Upward, And The Shift Frame Rotates Along With It. Under The Interaction Of The Various Transmission Parts, The Conveyor Chain Continues To Rotate. , And Slowly Lift The Coconut To The Bottom Of The Rack. The Top Of The Machine Is Equipped With A Fixed Blade, So That The Coconut Is Cut In Half Under The Action Of The Mutual Force Of The Blade And The Rack. The Half-cut Juice Flows Into The Juice Hopper. A Row Of Bars Is Installed Above The Juice Hopper To Prevent The Coconut Shell From Falling Into The Juice Hopper. The Bars Are At A Certain Angle, And The Coconut Shell Is Introduced To The Slag Hopper From The Bar.